NEXT WORKING DAY DELIVERY - Please place orders before 2:30pm (midday for Roland products)

NEXT WORKING DAY DELIVERY - Please place orders before 2:30pm (midday for Roland products)

Overview

FCX2000-60 (36 x 24")Superseding the Graphtec FC2250, the Graphtec FCX2000 is the ultimate solution for prototyping and small production runs of rigid materials without the use of a cutting die. Reduce media hate / processing time with Graphtec’s precision cutting precision cutting and dedicated software. Added offline (USB) operation enables users of all skill levels to easily process materials.

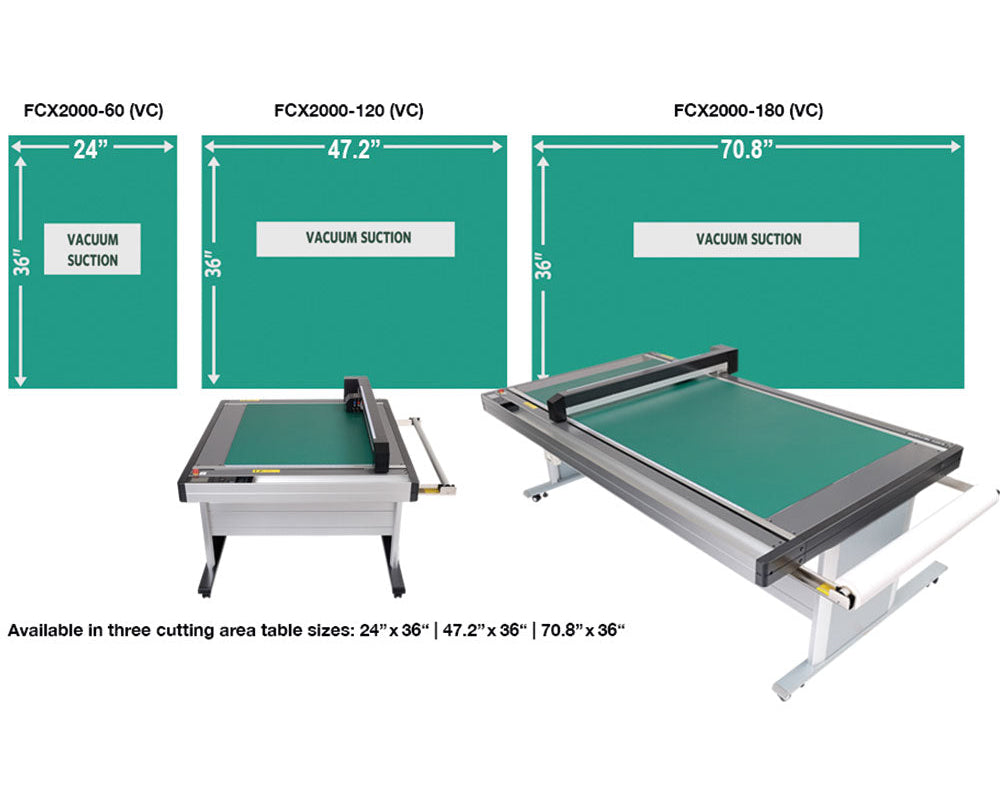

Model Options

- FCX2000-60 (36 x 24")

- FCX2000-120 (36 x 47.2")

- FCX2000-180 (36 x 70.8")

Effective cutting area: 1,200mm x 920mm

Superseding the Graphtec FC2250, the Graphtec FCX2000 is the ultimate solution for prototyping and small production runs of rigid materials without the use of a cutting die. Reduce media hate / processing time with Graphtec’s precision cutting precision cutting and dedicated software. Added offline (USB) operation enables users of all skill levels to easily process materials.

Graphtec 2 Studio Design Software included

Features

- The built-in Automatic Registration Mark Sensing system further simplifies contour cutting of printed materials.

- Incorporates ARMS to ensure precise cutting. Cut decals & other P&C application with ARMS.

- A tool lineup for cutting of thick paper and corrugated cardboard E/F/G grade.

- Fulfilling the max high pressure 1kg, and enables you to cut thick material.

- A USB2.0 interface.

- Software applications that improve work efficiency.

- Achieves a best-in-class cost performance.

- 4 models are available, differ in sizes and hold down methods

Superseding the Graphtec FC2250, the Graphtec FCX2000 is the ultimate solution for prototyping and small production runs of rigid materials without the use of a cutting die. Reduce media hate / processing time with Graphtec’s precision cutting precision cutting and dedicated software. Added offline (USB) operation enables users of all skill levels to easily process materials.

The FXC2000 features Graphtec’s newest Advanced Registration Mark Sensing System Version 6.0 for even more improved contour cutting of your pre-printed graphics for package prototyping, reflective sheeting and many other professional rigid applications—using Cutting Master 4, Graphtec Pro Studio, and including most industry standard cutting software

ARMS Copy Function

Cut data is able to be copied multiple times for streamlined productivity! Internally, the FCX2000 is able to scan the first four registration marks on the first sheet, and only requires scanning the first mark on subsequent (identical) sheets. This shortened scan detection method increases overall productivity.

Reverse Side Cutting and Creasing Method

Cutting and creasing of pre-printed packaging graphics is possible on the reverse (non-printed) side of the sheet. This method of reverse side cutting and creasing prevents damage and marking of the printed side. This option is currently available using Cutting Master 4 or Graphtec Pro Studio software with the FCX2000.

Expanded Contour Cutting Area

This included function expands the print and cut area to include objects outside of the registration marks! Production efficiency is enhanced and media waste is reduced

Supports Standard Crop Marks

Contour cutting pre-printed media is also possible using “standard crop marks.” This operation is available with the included Cutting Master 4 plug-in workflow

Reversed Colour Registration Marks

Registration marks are detectable when there is sufficient contrast against the mark and its background. Ultra glossy and reflective media offer challenges for accurate registration mark detection. With this reversed colour output, the sufficient contrast is brought back for the ability to contour cut pre-printed ultra glossy and reflecting sheeting.

Video

Specification

| Model name | FCX2000-60VC | FCX2000-120VC | FCX2000-180VC | ||

|---|---|---|---|---|---|

| Configuration | Digital servo system, Flatbed | ||||

| Media hold-down method | Vacuum suction | ||||

| Effective cutting area | 24 in x 36 in (610mm x 920mm) | 47.2 in x 36 in (1,200mm x 920mm) | 70.8 in x 36 in (1,800mm x 920mm | ||

| Mountable media (Y-axis) | 3 ft 1.4 in (950mm) | ||||

| Roll media support | Roll media stocker (manual feeding), supported media; width: up to 950 mm, weight: up to 5 kg | ||||

| Maximum cutting speed | 1 ft 3.7 inch/sec (400 mm/sec) (1 to 40 cm/s in 16 steps), in all directions | ||||

| Cutting force | Tool 1: Max. 4.9 N (500 gf), Tool 2: Max. 9.8 N (1 kgf) | ||||

| Cutting force settings | Tool 1: in 40 steps, Tool 2: in 40 steps | ||||

| Minimum character size | Approx. 10 mm square (varies with character font and media) | ||||

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ : 0.025 mm | ||||

| Distance accuracy | Max. 0.1% of the distance moved or 0.1 mm, whichever is larger (in plotting mode) (*2) | ||||

| Perpendicularity | Max 0.5 mm / 900 mm (in plotting mode) | ||||

| Repeatability | Max 0.1 mm (excluding contraction of media, in plotting/cutting mode) (*2) | ||||

| Standard interfaces | RS-232C, USB2.0 (High-Speed), and Ethernet (10BASE-T/100BASE-TX) | ||||

| Buffer memory | 2MB | ||||

| Command sets | GP-GL and HP-GL™ emulation (set by menu, or selects automatically by received data) | ||||

| Number of tools | Two tools | ||||

| Cutting blade, pen, and tool types | Cutting blade (supersteel), Pens (Water-based fiber-tip pen, oil-based ballpoint pen), and Creasing/scoring tool | ||||

| Others | ARMS, Reverse side Cutting/Creasing using ARMS, ARMS Copy function, Creasing, Cutting/creasing in multiple passes | ||||

| Power source | 100 to 240 VAC, 50/60 Hz (Auto switching) | ||||

| Power consumption | Max. 140 VA | ||||

| Pumps | 110V has 1.5 horse power, 220V has 2.5 horse power | ||||

| Operating environment | Temperature: +10 to +35 ºC, Humidity: 35 to 75% RH (non-condensing) | ||||

| Guaranteed accuracy environment | Temperature: +16 to +32 ºC, Humidity: 35% to 70% RH (non-condensing) | ||||

| External dimensions [W x D x H] (Approx.) |

W 52.9 x D 55.4 x H 36.6 in 1344 x 1409 x 930 mm (Including stand) |

W 76.1 x D 55.4 x H 36.6 in 1934 x 1409 x 930 mm (Including stand) |

W 99.7 x D 55.4 x H 36.6 in 2534 x 1409 x 930 mm (Including stand) |

||

| Weight (Approx.) | 167.5 lb (Including stand) (*3) | 218.2 lb (Including stand) (*3) | 225.7 lb (Including stand) (*3) | ||

| Compatible OS (*4) | Windows 10 / 8.1 / 8 / 7, Mac OS X 10.7 - 10.14 | ||||

| Included software (*4) (*5) | Cutting Master 4, Graphtec Pro Studio, Graphtec Studio(for Mac) | ||||

| Compatible Standards |

Safety | UL60950-1/cUL, CE marking (Low voltage and EMC) | |||

| EMC | FCC-A, EN55032-A | ||||

*1. Available in a limited region. Please contact your local representative of Graphtec.

*2. When operated with Graphtec specified media and conditions.

*3. Pump (blower) for vacuum suction media hold-down system is not included.

*4. For more information about Windows and Macintosh compatibility, please check the website or contact your local representative of Graphtec.

*5. The software can be used by downloading from Graphtec website.

Overview

FCX2000-60 (36 x 24")Superseding the Graphtec FC2250, the Graphtec FCX2000 is the ultimate solution for prototyping and small production runs of rigid materials without the use of a cutting die. Reduce media hate / processing time with Graphtec’s precision cutting precision cutting and dedicated software. Added offline (USB) operation enables users of all skill levels to easily process materials.

Model Options

- FCX2000-60 (36 x 24")

- FCX2000-120 (36 x 47.2")

- FCX2000-180 (36 x 70.8")

Effective cutting area: 1,200mm x 920mm

Superseding the Graphtec FC2250, the Graphtec FCX2000 is the ultimate solution for prototyping and small production runs of rigid materials without the use of a cutting die. Reduce media hate / processing time with Graphtec’s precision cutting precision cutting and dedicated software. Added offline (USB) operation enables users of all skill levels to easily process materials.

Graphtec 2 Studio Design Software included

Features

- The built-in Automatic Registration Mark Sensing system further simplifies contour cutting of printed materials.

- Incorporates ARMS to ensure precise cutting. Cut decals & other P&C application with ARMS.

- A tool lineup for cutting of thick paper and corrugated cardboard E/F/G grade.

- Fulfilling the max high pressure 1kg, and enables you to cut thick material.

- A USB2.0 interface.

- Software applications that improve work efficiency.

- Achieves a best-in-class cost performance.

- 4 models are available, differ in sizes and hold down methods

Superseding the Graphtec FC2250, the Graphtec FCX2000 is the ultimate solution for prototyping and small production runs of rigid materials without the use of a cutting die. Reduce media hate / processing time with Graphtec’s precision cutting precision cutting and dedicated software. Added offline (USB) operation enables users of all skill levels to easily process materials.

The FXC2000 features Graphtec’s newest Advanced Registration Mark Sensing System Version 6.0 for even more improved contour cutting of your pre-printed graphics for package prototyping, reflective sheeting and many other professional rigid applications—using Cutting Master 4, Graphtec Pro Studio, and including most industry standard cutting software

ARMS Copy Function

Cut data is able to be copied multiple times for streamlined productivity! Internally, the FCX2000 is able to scan the first four registration marks on the first sheet, and only requires scanning the first mark on subsequent (identical) sheets. This shortened scan detection method increases overall productivity.

Reverse Side Cutting and Creasing Method

Cutting and creasing of pre-printed packaging graphics is possible on the reverse (non-printed) side of the sheet. This method of reverse side cutting and creasing prevents damage and marking of the printed side. This option is currently available using Cutting Master 4 or Graphtec Pro Studio software with the FCX2000.

Expanded Contour Cutting Area

This included function expands the print and cut area to include objects outside of the registration marks! Production efficiency is enhanced and media waste is reduced

Supports Standard Crop Marks

Contour cutting pre-printed media is also possible using “standard crop marks.” This operation is available with the included Cutting Master 4 plug-in workflow

Reversed Colour Registration Marks

Registration marks are detectable when there is sufficient contrast against the mark and its background. Ultra glossy and reflective media offer challenges for accurate registration mark detection. With this reversed colour output, the sufficient contrast is brought back for the ability to contour cut pre-printed ultra glossy and reflecting sheeting.

Video

Specification

| Model name | FCX2000-60VC | FCX2000-120VC | FCX2000-180VC | ||

|---|---|---|---|---|---|

| Configuration | Digital servo system, Flatbed | ||||

| Media hold-down method | Vacuum suction | ||||

| Effective cutting area | 24 in x 36 in (610mm x 920mm) | 47.2 in x 36 in (1,200mm x 920mm) | 70.8 in x 36 in (1,800mm x 920mm | ||

| Mountable media (Y-axis) | 3 ft 1.4 in (950mm) | ||||

| Roll media support | Roll media stocker (manual feeding), supported media; width: up to 950 mm, weight: up to 5 kg | ||||

| Maximum cutting speed | 1 ft 3.7 inch/sec (400 mm/sec) (1 to 40 cm/s in 16 steps), in all directions | ||||

| Cutting force | Tool 1: Max. 4.9 N (500 gf), Tool 2: Max. 9.8 N (1 kgf) | ||||

| Cutting force settings | Tool 1: in 40 steps, Tool 2: in 40 steps | ||||

| Minimum character size | Approx. 10 mm square (varies with character font and media) | ||||

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ : 0.025 mm | ||||

| Distance accuracy | Max. 0.1% of the distance moved or 0.1 mm, whichever is larger (in plotting mode) (*2) | ||||

| Perpendicularity | Max 0.5 mm / 900 mm (in plotting mode) | ||||

| Repeatability | Max 0.1 mm (excluding contraction of media, in plotting/cutting mode) (*2) | ||||

| Standard interfaces | RS-232C, USB2.0 (High-Speed), and Ethernet (10BASE-T/100BASE-TX) | ||||

| Buffer memory | 2MB | ||||

| Command sets | GP-GL and HP-GL™ emulation (set by menu, or selects automatically by received data) | ||||

| Number of tools | Two tools | ||||

| Cutting blade, pen, and tool types | Cutting blade (supersteel), Pens (Water-based fiber-tip pen, oil-based ballpoint pen), and Creasing/scoring tool | ||||

| Others | ARMS, Reverse side Cutting/Creasing using ARMS, ARMS Copy function, Creasing, Cutting/creasing in multiple passes | ||||

| Power source | 100 to 240 VAC, 50/60 Hz (Auto switching) | ||||

| Power consumption | Max. 140 VA | ||||

| Pumps | 110V has 1.5 horse power, 220V has 2.5 horse power | ||||

| Operating environment | Temperature: +10 to +35 ºC, Humidity: 35 to 75% RH (non-condensing) | ||||

| Guaranteed accuracy environment | Temperature: +16 to +32 ºC, Humidity: 35% to 70% RH (non-condensing) | ||||

| External dimensions [W x D x H] (Approx.) |

W 52.9 x D 55.4 x H 36.6 in 1344 x 1409 x 930 mm (Including stand) |

W 76.1 x D 55.4 x H 36.6 in 1934 x 1409 x 930 mm (Including stand) |

W 99.7 x D 55.4 x H 36.6 in 2534 x 1409 x 930 mm (Including stand) |

||

| Weight (Approx.) | 167.5 lb (Including stand) (*3) | 218.2 lb (Including stand) (*3) | 225.7 lb (Including stand) (*3) | ||

| Compatible OS (*4) | Windows 10 / 8.1 / 8 / 7, Mac OS X 10.7 - 10.14 | ||||

| Included software (*4) (*5) | Cutting Master 4, Graphtec Pro Studio, Graphtec Studio(for Mac) | ||||

| Compatible Standards |

Safety | UL60950-1/cUL, CE marking (Low voltage and EMC) | |||

| EMC | FCC-A, EN55032-A | ||||

*1. Available in a limited region. Please contact your local representative of Graphtec.

*2. When operated with Graphtec specified media and conditions.

*3. Pump (blower) for vacuum suction media hold-down system is not included.

*4. For more information about Windows and Macintosh compatibility, please check the website or contact your local representative of Graphtec.

*5. The software can be used by downloading from Graphtec website.

You may also like

Request for Quote

TO ADD MULTIPLE ITEMS TO YOUR QUOTE, PLEASE FILL QTY FIELD THEN CLICK ON "ADD TO QUOTE"